|

CARBON

CAPTURE

& STORAGE

Pleas use our

A-Z INDEX to

navigate this site

H&SE

UK -

CCS is a new process and there are currently no commercial scale projects operating in GB. Future CCS operators will be able to make sure that their CCS processes are safe for workers and members of the public by complying with existing health and safety legislation and by taking a proportionate approach to managing CCS risks.

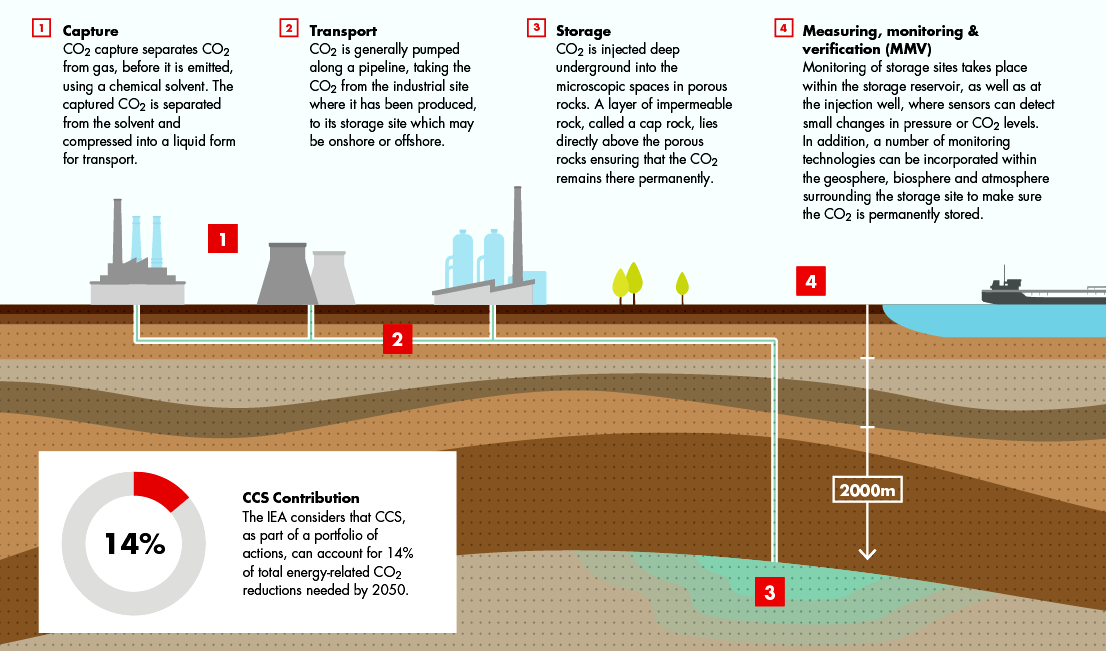

Carbon capture and storage (CCS) (or carbon capture and sequestration or carbon control and sequestration) is the process of capturing waste

carbon dioxide (CO2) usually from large point sources, such as a

steel, cement,

factory or power plants, transporting it to a storage site, and depositing it where it will not enter the atmosphere, normally an underground geological formation.

The aim is to prevent the release of large quantities of CO2 into the atmosphere from heavy industry.

It is a potential means of mitigating the contribution to

global warming and ocean acidification of

carbon dioxide emissions from industry and heating. Although CO2 has been injected into geological formations for several decades for various purposes, including enhanced

oil recovery, the long term storage of CO2 is a relatively new concept.

Direct air capture is a type of CCS which scrubs CO2 from ambient

air rather than a point source.

THREE

CAPTURE TECHNOLOGIES

Currently there are three different capture technologies available to capture CO2:

- Post-combustion capture of CO2 occurs after the burning of fossil fuels. CO2 is separated from flue gas when it is passed through a liquid which causes a chemical reaction. This is also called scrubbing.

-

Pre-combustion capture is where CO2 is separated or removed prior to the burning of fossil fuels. The pre-combustion technology converts fossil fuels into a gas made up of CO2 and Hydrogen (H2). These gases are then separated, with H2 used to fuel the power plant.

-

Oxyfuel combustion burns fossil fuels with nearly pure oxygen. The flue gas produced only contains CO2 and steam. These are separated by a cooling process with the water condensing leaving a flue gas of almost pure CO2.

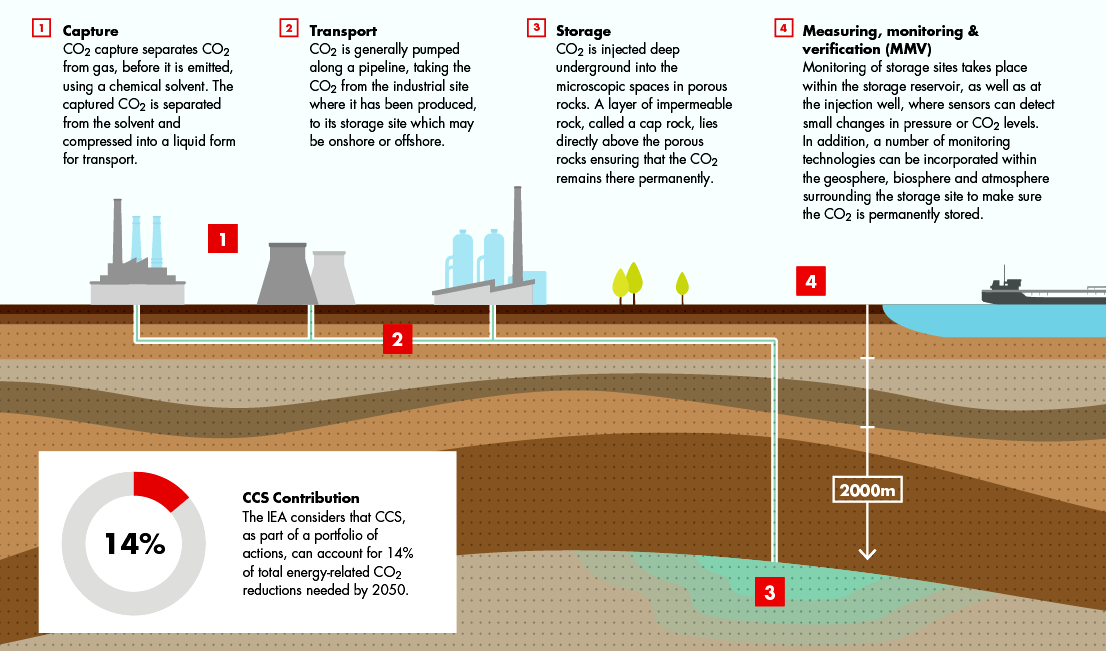

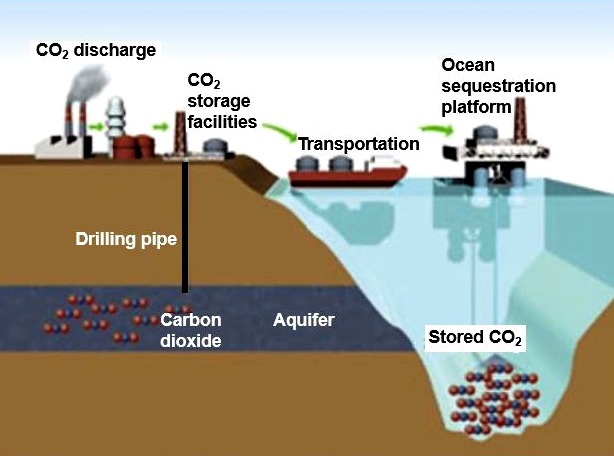

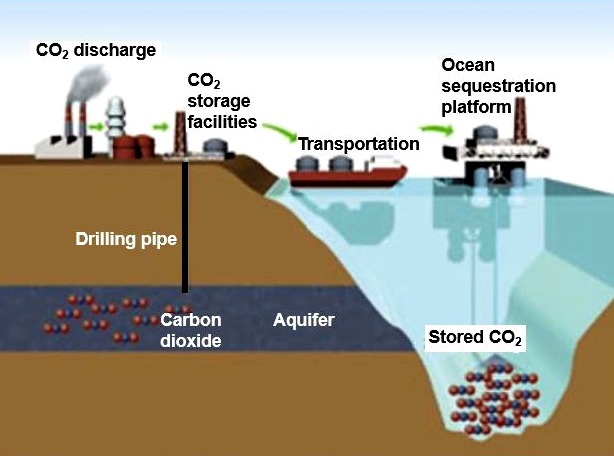

CO2 Transport

CO2 is likely to be transported by pipeline from the capture site to an offshore installation located near a suitable underground reservoir. However, in some cases, tankers may be used to transport CO2 to offshore installations.

CO2 Storage

The final stage of the CCS process involves injecting CO2 at high pressure from an offshore installation into a deep geological formation such as depleted oil or gas reservoirs, or a saline aquifer. Potential storage sites will be chosen on the basis of their ability to safely contain stored CO2 without leakage.

MAJOR HAZARD POTENTIAL

In CCS operations it is likely that CO2 will be handled close to, or above, its critical pressure (73.82 bar) where many of its properties are similar to that of a liquid. In this state it is often referred to as ‘dense phase’, whereas above critical temperature (31.04°C) and pressure it is referred to as ‘supercritical’. Significant hazards associated with dense phase or supercritical CO2 arise when pressure falls suddenly or is lost completely.

CO2 is not currently defined as a dangerous substance under the Control of Major Accident Hazards Regulations 1999 (COMAH) or as a dangerous fluid under the Pipelines Safety Regulations 1996 (PSR). In June 2011 HSE published Assessment of the major hazard potential of Carbon Dioxide PDF. This report concluded that CO2, based on the evidence available at that time, has major accident hazard potential if released at, or above, its critical pressure. However, where the risks are properly controlled the likelihood of a major hazard incident is expected to be very low, as in other similar processes in the energy, chemical and pipeline industries. HSE is committed to keeping CCS risks under review and will consider extending existing major accident hazard legislation to cover CCS if this is justified by the evidence.

In order to achieve a similar safety record to other energy, chemical and pipeline industries the CCS sector needs to continue to address the limitations of current knowledge regarding the control of risks from dense phase and supercritical CO2.

In particular the following issues require further research and validation:

1. Modelling releases and dispersion

2. Separation distances

3. Design and operation of plant and pipelines

1. Modelling releases and dispersion

The ability to foresee loss of containment scenarios and accurately predict the dispersion of CO2 and its consequences are a fundamental element of CCS risk assessment. Currently the behaviour of CO2, when released in its dense and supercritical phases, is not yet fully understood. The CCS industry is continuing research into the use of appropriate dispersion models and these are being validated through appropriate scale experimental work. This will provide HSE and duty holders with a thorough understanding of how dense phase and supercritical CO2 behaves during foreseeable large-scale releases.

2. Separation Distances

Since CO2 is not currently defined as a dangerous substance under the Control of Major Accident Hazards Regulations 1999 (COMAH) or as a dangerous fluid under the Pipelines Safety Regulations 1996 (PSR) HSE does not provide Land Use Planning (LUP) advice for CO2 capture, transport or storage.

However, for LUP purposes HSE uses Dangerous Toxic Load (DTL) to describe a substance’s airborne concentration and duration of exposure which would produce a particular level of toxicity in the general population. Potential CCS operators should be informed by Assessment of the Dangerous Toxic Load (DTL) for Specified Level of Toxicity (SLOT) and Significant Likelihood of Death (SLOD) when designing CCS CO2 capture sites and offshore installations and deciding pipeline routes.

3. Design and operation of plant and pipelines

When designing, fabricating, maintaining and operating plant and pipelines for handling and transporting dense phase or supercritical CO2 it is important that the full significance its physical properties, at the temperatures, pressures and compositions required, are fully recognised and managed.

Detailed standards and codes of practice written specifically for the design and operation of dense phase or supercritical CO2 plant and pipelines are still being developed. However, although general process engineering and pipeline standards exist (such as those for natural gas) that may be applied to CCS these may not be sufficient to ensure adequate containment for CO2 under all conditions.

CHRIS

HUHNE -

“CCS has a key part to play in ensuring that we can keep the lights on at the same time as fighting climate change. The International Energy Agency has estimated that globally 3,400 CCS plants will be needed by 2050 if we are to meet our critical target of 2 degrees above pre-industrial levels. The UK has the skills and opportunity to lead the world in this technology, which is why in the spending review we committed to investing up to a billion pounds in CCS.”

Chris Huhne, former Secretary of State, Department of Energy and Climate Change

Carbon Capture and Storage (CCS) is a technology that can capture up to 90% of the carbon dioxide (CO2) emissions produced from the use of

fossil fuels in electricity generation and industrial processes, preventing the carbon dioxide from entering the atmosphere.

Carbon, Capture and Storage (CCS)

could be a useful technology for tackling climate change if it

can be delivered in an affordable way.

CCS is one of a suite of technologies that will all be required to combat climate change, including renewables, nuclear and energy efficiency. The importance of CCS as one of the tools against global warming is highlighted in a report by the International Energy Agency, which found that CCS could contribute to a 19% reduction in global CO2 emissions by 2050, and that fighting climate change could cost over 70% more without CCS.

CCS can be applied to fossil fuel-fuelled electricity generating plant, such as coal or gas fired power stations. Fossil fuel plants with CCS have a key role to play in providing a balanced energy supply, which can cope with rapid changes in demand, and intermittency of supply, which nuclear and renewables cannot. CCS will play a key role in the UK to provide secure, affordable, low carbon

electricity in the transition to a low-carbon economy.

CCS can also significantly reduce emissions from industry such as cement, steel and chemical industries, and in many instances, is the only currently viable technology to do so. CCS when combined with biomass can result in negative CO2 emissions. As plants grow, they absorb CO2 from the atmosphere. When they are burnt to produce power, if the CO2 is captured and stored there is a net reduction in CO2 in the atmosphere.

AFFORDABILITY

The cost of reducing carbon dioxide (CO2) emissions will be dramatically higher without CCS, up to 70% higher internationally (according to the IEA).

The cost of individual CCS project can vary substantially depending on the source of the carbon dioxide to be captured, the distance to the storage site and the characteristics of the storage site.

The cost of capturing the carbon dioxide is typically the greatest cost of a CCS project. Recent studies conclude that the first CCS projects in the power sector are likely to cost between €60 – 90 per tonne of carbon dioxide abated although these costs are expected to decline significantly reaching €35 – 50 in the early 2020s primarily as a result of cost reductions for carbon dioxide capture.

The

remaining question is who will pay for these services? Will it

be the United

Nations, G20

or other group.

CURRENT

PROJECTS @ 2017 - SHELL

According

to their website there are 21 large-scale CCS projects in operation or under construction globally, with a combined capacity to capture around 40 million tonnes of CO2 each year. All projects presently in construction (five as of January 2017)

were expected to be operational by the end of 2017.

Shell is sharing the knowledge and experience gained in CCS through various working groups. The Oil and Gas Climate Initiative’s (OGCI) Climate Investments partnership – comprising 10 major oil and gas companies, including

Shell – has made CCS one of its priority areas.

Shell is also investing in the future Gorgon CO2 injection project in Australia, the CCS Test Centre in Mongstad, Norway, and the Qatar Carbonates and Carbon Storage Research Centre in the UK.

Quest, Canada

In Alberta, Canada, Shell operates a joint venture (Shell interest 60% in 2016) that has developed the first commercial-scale CCS facility for CO2 extracted from our oil sands operations. The Quest facility is designed to capture up to 35% of the current CO2 emissions from the Scotford Upgrader – a plant where bitumen is processed into synthetic crude oil. The captured CO2 is stored in a porous rock layer about 60 kilometres away and more than 2 kilometres under ground. The provincial government of Alberta and the federal government of Canada have provided C$865 million to support the development of Quest.

In 2016, in its first full year of operation, Quest safely captured and stored more than 1 million tonnes of CO2 ahead of schedule. This is equivalent to the emissions from about 250,000 cars. Shell and our joint-venture partners are freely sharing any data or intellectual property generated by the Quest project to help others advance CCS projects and demonstrate the technology’s value on an industrial scale.

In March 2017, Shell agreed to sell to Canadian Natural Resources Limited (Canadian Natural) its 60% interest in the Athabasca Oil Sands Project (AOSP), its 100% interest in the Peace River Complex in-situ assets including Carmon Creek, and a number of undeveloped oil sands leases, all in Alberta, Canada. In a related transaction, Shell and Canadian Natural have agreed to jointly acquire Marathon Oil Canada Corporation, which has a 20% interest in the AOSP. Following these transactions, Shell will continue as operator of the Scotford Upgrader and Quest.

Monitoring Quest

Quest is designed to meet all the requirements for the safe and permanent storage of CO2. We have developed a rigorous monitoring programme, agreed by the government and verified by a third party, to ensure that the CO2 remains safely and securely underground. This includes continuous pipeline monitoring and early-warning systems, groundwater sampling and 3D seismic surveying. Throughout the development of Quest, we conducted an extensive consultation programme with nearby communities. We share results from our monitoring programme with them.

Shell Cansolv

CCS technology developed by Shell Cansolv, a subsidiary of Shell, is used at the power station Boundary Dam in Saskatchewan, Canada. It is SaskPower’s largest coal-fired power station and a significant source of power for the region. Both sulphur dioxide and CO2 are captured from the power station. We continue to support SaskPower to improve the application of the technology.

JUST

LIKE A GLASS BOWL -

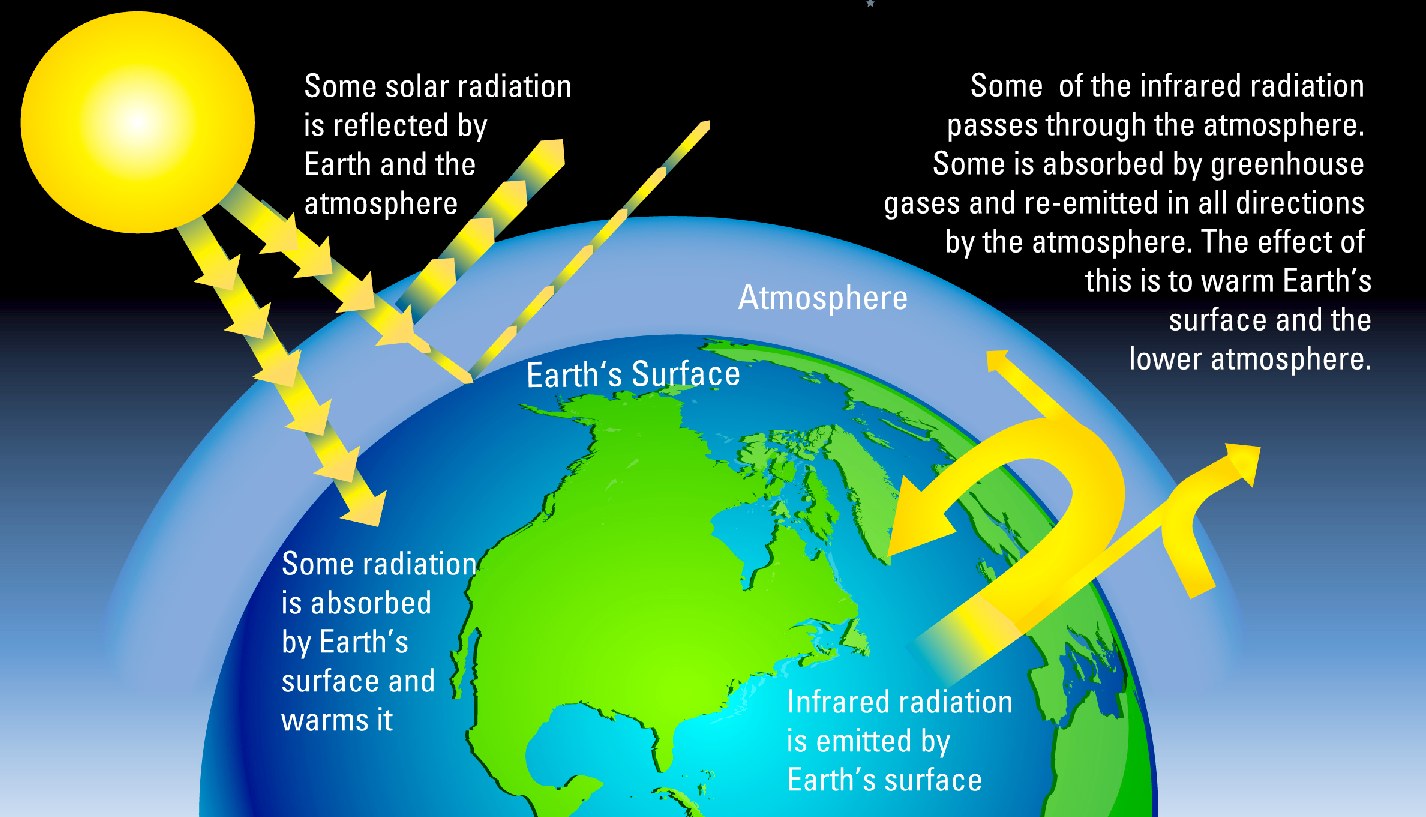

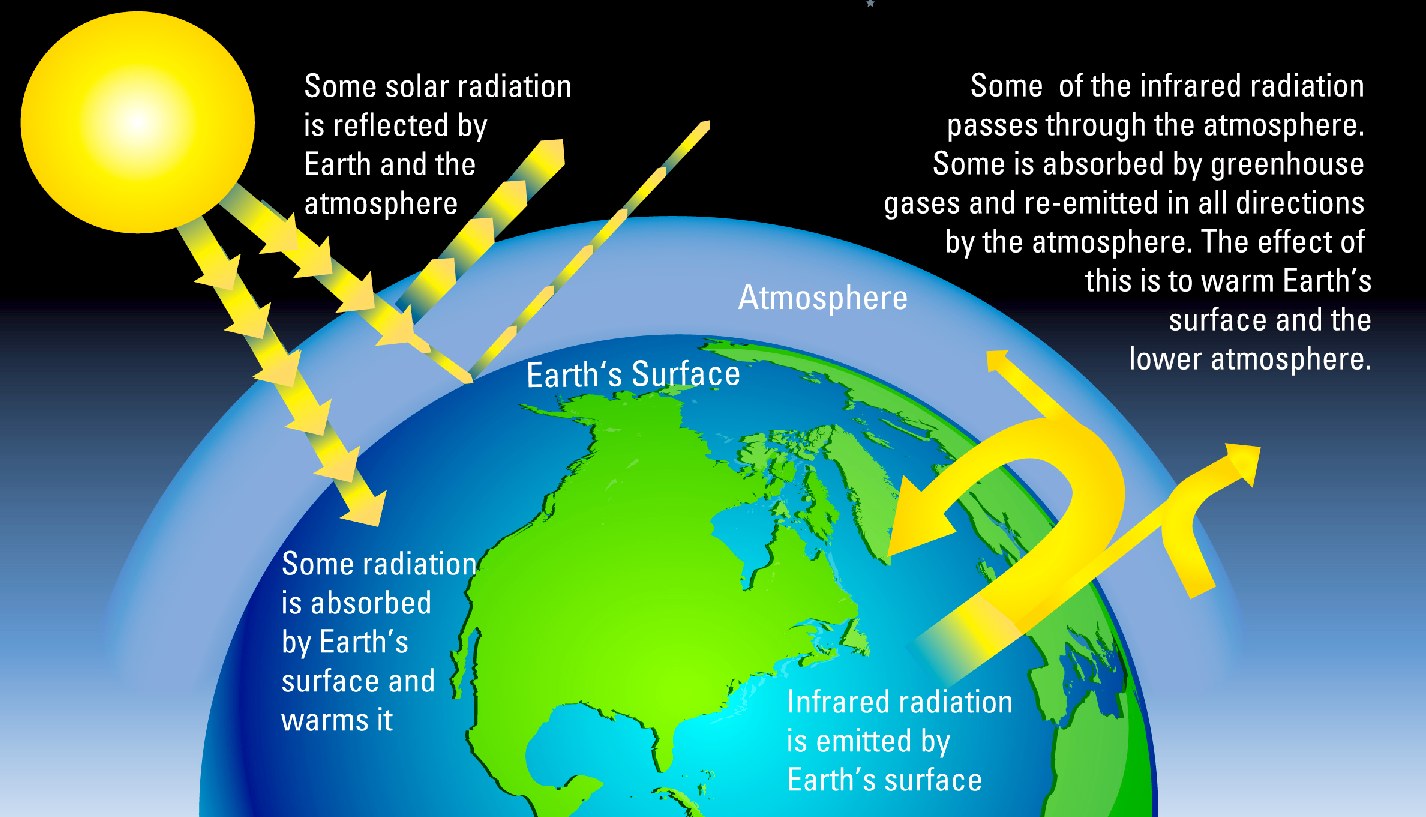

Radiation from the sun would be reflected out into space, but

with more greenhouse gases in the atmosphere some radiated

heat is absorbed and re-emitted back to earth just as if we

lived in a greenhouse.

LINKS

& REFERENCE

http://reports.shell.com/sustainability-report/2016/energy-transition/our-work-to-address-climate-change/carbon-capture-and-storage.html

http://www.hse.gov.uk/carboncapture/about-carbon.htm

http://www.ccsassociation.org/what-is-ccs/

THE

BLONDE YEARS -

Business success does not appear to go hand-in-glove with

conservation needs,

where there is no profit in doing the right thing, other than

saving the planet. But you cannot bank saving the planet. This begs

the question, do we want hard nosed business ethics

entering the political arena with Presidents like

Donald

Trump. Want it or not the USA have got it because he used

his climate change dollars to buy the presidency. Should that

be allowed? We'd suggest a cap on allowable election expenses.

We live in hope that the entrepreneur might develop a

conscience while still in office.

Pleas use our

A-Z INDEX to

navigate this site

This

website is provided on a free basis as a public information service.

copyright © Climate Change Trust 2019. Solar

Studios, BN271RF, United Kingdom.

|