|

CC CHALLENGERS: CROSS CHANNEL

Please use our A-Z INDEX to navigate this site where page links may lead to other sites

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Cross Channel Challenger (CCC) is a project currently on the drawing board that is looking for backing to develop a coastal cruiser that is zero carbon.

We should first of all stress, that this project has been costed to come in at around the £350k mark [100%] (including the time, facilities and hire provided by the leads) as a real bargain basement starter package.

Hence the vessel does not include the latest lithium batteries or higher output solar cells, nor exotic materials in the build - and the hull design is very simple. It is a budget vessel to allow us to get the R&D ball rolling. The project includes no research as to improvement of rotary sails, or navigation routing. The vessel is also considered small for cross channel work with a hull compromise to keep the cost of the project low.

Whereas, as the length of a hull grows and efficiency of revolving sails, and the hydrodynamics improve, so does the range and speed, so bear this is mind. Things can only get better such as with the Atlantic Challenger, a more comprehensive vessel incorporating advanced navigation and the latest energy technology, but is considerably more costly to develop and will require serious collaboration with European partners.

The theoretical performance of the 'Channel Challenger' is therefore lower than we would like, but is considered to be a useful stepping stone. For example we might expect 16.7kW of harvesting power, for around 12 tons of vessel (semi-developed), multiplying the current benchmark of .98kW/ton x 1.42 to give 1.39kW/ton. Not exactly startling, but a nice little gain, especially with a dual energy harvesting system that might use the wind as rotary sails and generators autonomously - a world first.

Sailing craft have been crossing the oceans zero carbon for hundreds of years at respectable speeds ending with the tea clippers managing 12-15 knots. There is every reason to expect that a modern purpose designed vessel might achieve such velocities routinely with suitable navigation management.

For cross channel work, the operational speed might be raised to 15 - 25 knots using part of a (stationary-shore-charge) reserve, supplemented with live incoming energy. A study as to the possibilities would be part of this project.

WHAT IS IT ?

It's a trimaran that is zero carbon, propelled only by the sun and the wind, following on from the development of a land based rig in 2019 (yet to be completed) that showed us a path to what might be possible with relatively little in terms of R&D investment.

WHO WILL BUILD IT ?

A British team comprised of Bluebird Marine Systems Ltd and the Cleaner Ocean Foundation Ltd working with subcontractors and academia. They are set to build this low budget coastal cruiser with cross-channel capability if the specification is upgraded. The basic hull design though, stays the same.

Nelson Kay: CAD design (and where needed) welding fabrication

and mechanics Richard

Whelan: Logistics & purchasing Terry Valeriano: H&S and PT

Subcontractors: Details available on request.

The CCC will be managed on a not for profit basis, with a view to demonstrating a formula for blue water ocean transports, the aim being to interest commercial ship builders. The concept may be scaled up from the at present medium boat size, to cargo and cruise ships. The secret being the power to weight ratio and energy storage capacity balanced against load carrying ability. It's all about defining a formula for delivering the goods.

WHEN WILL THEY BUILD IT ?

Aiming for a start on this project in 2020, the actual start date is dependent on raising sufficient interest so that materials, manufacturing and equipment costs are covered by grants or maybe even crowd funding. Project management, design leadership, and other facilities will be contributed by the leads.

END ELEVATION - In this drawing the solar wings are shown folded out horizontally as though the sun was overhead. The wing arrays, comprised of twin 17 panel units, can track the sun, 34 moveable panels in all. The central array comprised of 24 panels, is fixed to the superstructure. The wind turbines are in-effect rotary sails.

As rotary sails a 40mph wind on two 5m diameter rotary sails would generate a theoretical 767kg of force (thrust) [1,690lbs]. On two 4m dia sails: 494kg [1089lbs]. Wind speed is of course variable and directional, but on average the forces generated will decrease passage time. For larger vessels traversing trade routes, the advantage could be considerable. For this budget experiment, we'd be using 2.25m turbines that might be upgraded to 5m for ongoing experiments after the 75 week delivery target.

Please note that drawings of the Cross Channel Challenger are Design Copyright © September 8 2019, and the hull configuration and energy harvesting system are patent protected.

WHY DO THEY WANT TO DO THIS ?

With the present climate emergency likely to worsen without some immediate action, vessels that are zero carbon should be put to good use wherever possible.

At the present time there appears to be no system for marine craft that would allow for the intelligent dual harvesting of solar and wind energy in such autonomous combination, so as to be able to provide sufficient energy for propulsion at speeds of up to 10

knots for coastal work

and 15-20 knots for channel crossings. Ten knots being a practical working speed in terms of cargo delivery

services - with long range zero carbon cruising as a

possibility with further (long range)

development of the concept.

INTERNATIONAL MARITIME ORGANIZATION

Where the International Maritime Organization are aiming for a 40% reduction in greenhouse gas emissions for 2030, we should like to develop an automated solar and wind energy harvesting system for boats, that may be up-scaled for ships, to provide power to weight ratios between 1.12kW continuous and 3.6kW peak, per ton of vessel (specs dependent) Such targets require computer automated solar and wind turbine tracking to minimise shading, lightweight structures and integrated

hydraulics.

MULTI PURPOSE - The same basic hull form can be converted to an ocean or river cleaning machine with a bolt on SeaVax head, here shown in red - or a net-free zero carbon fishing vessel. We have designed the hulls in such a way that they can be configured to run in two directions - what is perceived as backwards being for plastic cleaning duties - should policies change to make ocean cleaning equitable. These drawings are Design Copyright © September 8 2019, and the hull configuration and ocean cleaning system are patent pending.

ECONOMICS

How much money might operators save in swapping their gas-guzzling coastal hoppers for clean solar powered vessels all depends on the cost of building this kind of design, the cost of maintaining the solar panels, the eventual cost of replacement batteries and any tax breaks that might be offered to help kickstart the zero carbon revolution.

Hydrogen Fuel Cell powered ferries are presently under development, despite the inherent complexity and dangers in dealing with an explosive gas, not to mention the reduced energy delivery from solar and wind power, that runs counter to Circular Economics and sustainable best practices. See the Scottish Isles study June 2019, Norled (Norwegian/French) and CARB: San Francisco Bay projects from 2018 and fuel supply problems for the FCS Altsterwasser in Hamburg 2014.

Doubtless there will be more on this as projects develop and policy makers push forward their clean ocean agendas.

Many ferry services might benefit from up-scaled designs. It is hoped that eventually long haul passages may be offered such as across the Atlantic. Operators, hence potential end users in the English Channel include: Brittany Ferries - DFDS - HoverSpeed - StenaLine and P&O Ferries.

FAST SOLAR - Delft University (Netherlands) set an offshore speed record of 35kph in this solar powered trimaran during a 4 hour marathon.

THE

PROJECT

PONTOON HULL FLOATS - The trimaran configuration of the pontoons. You cannot get much simpler than this. The 3 pontoons share the same nose and tail cone profile to keep costs down. The middle hull is slightly longer than the two outriggers. These are only draft designs that need to be re-drawn with details once a 1/10th scale model has been built and tested, such as to incorporate any obvious improvements. The Foundation has an in-house model maker and easy access to a water basin for stability testing, etc. Design Copyright © September 2019, Cleaner Ocean Foundation Ltd.

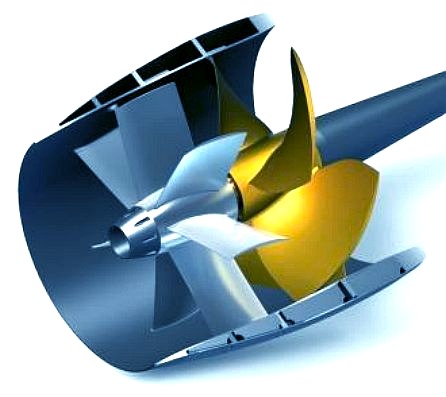

The hull of the vessel will be of welded construction in 5083 alloy, in three sections as sub-assemblies in a trimaran configuration, or stabilised mono-hull design along similar principles to the Cable & Wireless Adventurer (Nigel Irens), in that a slender hull reduces wave drag, hence propulsive power. Such slender hulls would roll unacceptably without outriggers to provide comfort for the operators.

ANGULAR MOVEMENT - The picture shows the angle of rotation of the moveable wind turbines on a collapsible (space frame) mast that is raised and lowered using hydraulic rams. The wind turbines work with the solar panels using computers and sensors to maximize the collection of energy from nature. Design copyright © 21-09-19 Cleaner Ocean Foundation Ltd, all rights reserved.

Part of the project is mechanical design. In particular the stressing of such a super-structure above hull height to keep structural mass low, hence the center of roll. The superstructure is designed to provide a frame with bearing points well above the waves, to allow for a degree of movement necessary for the solar arrays to be able to track the sun and for the wind turbines to be free to move away and high above the solar arrays for best turbine performance, Stressing of the moveable mast is included in this project to be able to reach far above the deck is normal operation, so that the turbine blades are operating in undisturbed air.

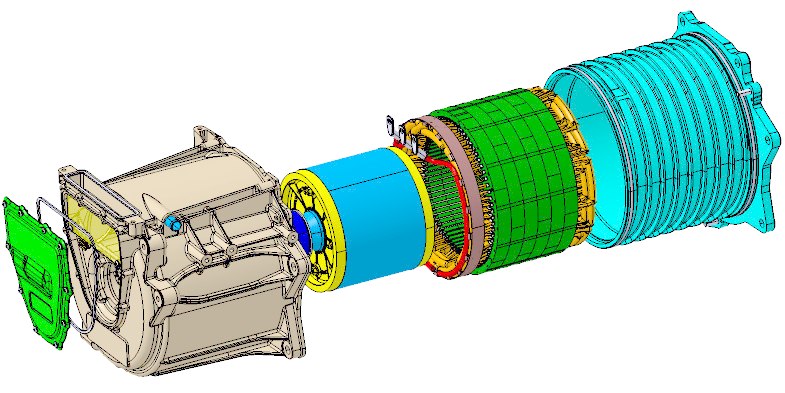

ECONOMIES OF SCALE - With more than 133,000 i3 units sold to 2018, it is likely that there will be quite a few serviceable second user battery packs coming into dealers from part exchanges. In any event as higher output cells are released, those with lesser capacity will be looking for new uses. It has been suggested they might power homes.

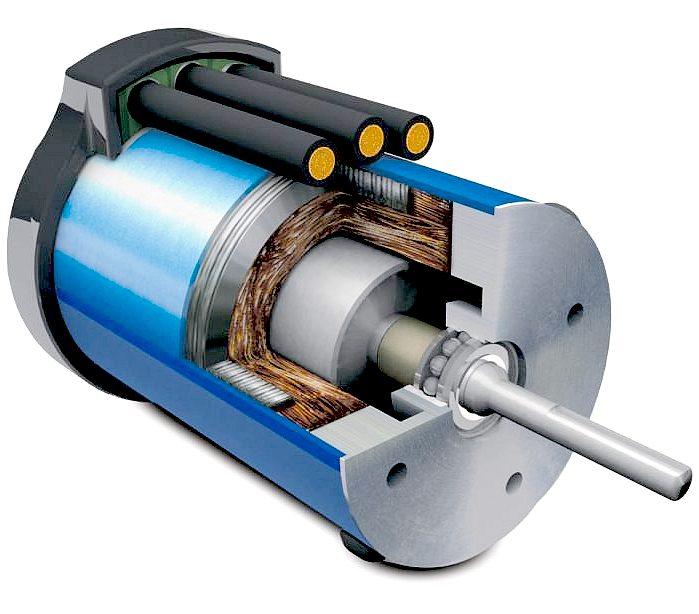

LITHIUM UPGRADE

Usefully, with BMW introducing their 120Ah battery packs for the i3 hatchback in 2019, there could be a supply of 60Ah packs at keen prices from car owners upgrading. Five of these packs powering two of the 125kW 360v motors would improve the performance and range of a short hop ferry with 110kW/hrs of energy storage for faster channel crossings. The i3 motor is a hybrid synchronous unit that is liquid cooled and reasonably efficient.

Bluebird Marine and Cleaner Ocean Foundation have been running a BMW i3 for about 3 years. The 2019 model i3 got the long-awaited 120 Ah battery cells from Samsung SDI. The 120 Ah battery cells give the battery pack a total capacity of 42.2 kWh (96 x 120 Ah x 3.667 V). The i3 ranked third among all-electric cars sold worldwide from 2014 to 2016. Global sales since inception totaled more than 133,000 units through the end of 2018, with 83,615 units sold in Europe.

PLAN VIEW - This drawing shows 58 solar panels and 2 wind turbines to provide 16.7kW of generating power peak. The proposal is for 36 panels and one wind turbine for 11.8kW . The passenger area is partly enclosed and partly exposed, though the layout can be changed to provide all open seating or all closed for up to 40 passengers. Please note that these drawings are Design Copyright © September 8 2019, and the hull configuration and energy harvesting system are patent protected.

INNOVATIVE ASPECTS OF THE PROJECT ?

ANGULAR MOVEMENT - The picture shows the angle of rotation of the moveable solar arrays. Design copyright © 21-09-19 Cleaner Ocean Foundation Ltd, all rights reserved.

ARRAYS FOLDED - The picture is an example of how the solar arrays fold over each other when stowed, seen in end elevation. See the plan view diagram below. Design copyright © 27-04-19 Cleaner Ocean Foundation Ltd, all rights reserved.

ARRAYS OPEN - This diagram shows the solar arrays in blue - open in plan view (from above) such that they present flat on to an overhead sun. Note no shading of the solar panels by the wind turbines when overhead, and that the turbines can be lowered and furled to prevent shading at different course headings. Design copyright © 29-04-19 Cleaner Ocean Foundation Ltd.

Experimentation, including the incorporation of new ideas in combination is needed to push forward the boundaries of human knowledge. By incorporating the separate elements that are known to function to some degree individually, we may identify the successful elements of the design, to be set down as a test bed for further improvements.

This research and development, if it is successfully demonstrated as described, offers one potential solution to the search for long range zero carbon ships of the future.

ENERGY SECURITY - Such development could free us from the oil based economy currently fueling global warming, amid uncertainties of supply following the attack on Saudi Aramco. Drones bombed the Abqaiq facility in Saudi Arabia and the Khurais oil field, operated by the state-owned Saudi Aramco on the 14th of September 2019. The plants produce nearly 6% of the world's oil, and half of Saudi's oil, with the attack cutting output by 5.7 million barrels a day. Energy stability holds the potential to quell many conflicts, as does food security. Solar assisted electric cars and solar powered shipping could help to reverse climate change and foster amicable international relations.

HOW MUCH WILL THE PROJECT COST ?

- Batteries and motors will be around £18k - Hydraulic components around £5.4k - Alloy hull around £56k - Stressing £27k - Project management £40.5k - Technicians £36 - Precision engineering £10k - Skippers £4.5k Subtotal £ 224.400 - Contingency (11%) £24.684 Total £ 249,084

The leads will make a 30%+ contribution of up to £100k, adding facilities, equipment, administration and legal.

Generally in Europe, Research & Innovation funding at conceptual level may justify 100% funding.

The

leads on this project are sufficiently keen to see it take off that they

will contribute significant time and resources to offset some of the work packages,

the aim being to reduce the actual cost to around 70% of the total. This is

by way of an effort to accommodate external contributors. At the level of funding

published herein readers will understand that the project is deliberately basic. It

can though be upgraded should suitable follow on calls and interest be generated.

SUPERSTRUCTURE SIDE, PLAN, END ELEVATIONS - The frame is a very simple design to keep the cost down and yet it is light and strong. This section of the Cross Channel Challenger may be built in a very small boatyard or fabrication factory. The modular design makes it easy for multiple suppliers to work on parts of the vessel at the same time to speed up production, with all parts being delivered to a single assembly point. The superstructure supports the solar panel and wind turbine mounts as well as seating and helm positions. Design Copyright © September 2019, Cleaner Ocean Foundation Ltd.

PROJECT PLAN: estimated 75 week duration in month size bites

WEEKS

1 - 16: Land based solar and turbine rig alongside 1:10 model build

1 - 16: Install solar panels on Transit rig and testing of the mechanics of this system in-house in dedicated workshops. In tandem, the hullform would be built as a 1/10th scale model for floatation tank testing from week 10.

WEEKS 17 - 32: Computer code debug harvesting system and test of model in water basin

17 -32: Ten* weeks would be allocated to debugging computer programs and running the machinery. In tandem, the model would undergo water tank testing and detail design revisions incorporated in full size CAD drawings.

WEEKS 33 - 48: Construction phase full size hull fabrication with subcontractor input

33 - 48: This month would mainly be sourcing materials and parts, including quantifying with spare metals and welding consumables and spare parts to ensure that the fabrication stage was as smooth as could be, given that there are always problems in supply and possibly even with quality control.

WEEKS 49 - 64:

49 - 64: The boat would be assembled at a local venue convenient to Eastbourne on the south coast where there is a marina with an outer harbour that is suitable, joining pontoons to superstructure, then fitting solar wings and masts. Other equipment would then be fitted wired up and connected, including the helm controls and basic instruments for coastal operation. Once fitted, the propulsion motor and energy harvesting systems would be tested.

WEEKS 65 - 75

65 - 75: Finally, in the last 10 weeks the zero carbon ferry would be launched and tested at sea in a series of small shakedown cruises, leading to a coastal cruise and return, from Eastbourne to Brighton and back. The data will be logged for performance evaluation with particular emphasis on scaling up the concept for consideration by ferry operators.

Hydraulics will come from our regular supplied of equipment, solar panels to be sourced at best market rate.

Where expressions of interest have in the past been received from academia, the team hope to collaborate with UK universities to assist with stressing of the structure, mast and moveable solar arrays. The Foundation has its own test tank for basic stability and model wind turbine testing.

The Foundation has basic welding fabrication equipment in MIG and TIG with spool-on-gun for alloy MIG work. The Foundation has convenient use of a large trailer mounted welding generator for portable operations during the assembly stage of boat fabrication.

OVERRUN CONTINGENCY

Should the project not be completed within the allotted 75 weeks, the Leads undertake to take the vessel to the agreed stage of completion at their own cost, using their own facilities and best endeavours.

BRITISH INNOVATION - A popular and fast way to get from Portsmouth to the Isle of Wight was by the Hoverspeed service. Hoverspeed eventually moved from hovercraft into high speed ferries, presumably because the operating costs of such technological marvels was too high. In order to be able to schedule commercial services, the hover craft concept of Sir Christopher Cockerell had to be perfected. The patent was declared a secret by the Ministry of Supply, hence preventing disclosure, Cockerell had to wait for two years until 1957 when he heard of a similar invention being developed that overcame military objections, after which he managed to secure funding to develop his invention. The SR.N1 prototype was built by Saunders-Roe. Ahead of schedule on 31st May 1959, the seven-ton craft flew, eight months after the commencement of design work. On 25th July she made a crossing of the English Channel, from Calais to Dover, with the inventor onboard.

CONTACTS

Nelson Kay Project Coordinator Climate Change Challengers Cleaner Ocean Foundation & Bluebird Marine Systems Ltd Solar Studios BN271RF United Kingdom

LINKS & REFERENCES

http://www.climatechangechallenge.org/ http://www.blue-growth.org

GUINNESS BOOK OF RECORDS - MS Turanor PlanetSolar (Switzerland) navigated the world in a westward direction from Monaco in 1 year 7 months and 7 days from 27 September 2010 to 4 May 2012. We wonder why nobody has attempted to improve on this design, to challenge the record in the intervening seven years.

TRANSFERABLE TECHNOLOGY - The design of the Climate Change Challenger might be adapted to Cargo, Container, Cruise and Ferry designs, without needing to radically alter port facilities. The designs above are not representative of adaptations of the concept, but serve to illustrate the thinking of other design houses.

Please use our A-Z INDEX to navigate this site

ADRIATIC SEA - ARCTIC OCEAN - ATLANTIC OCEAN - BALTIC SEA - BAY OF BENGAL - BERING SEA - CARIBBEAN SEA CORAL SEA - EAST CHINA SEA - ENGLISH CHANNEL - GULF OF GUINEA - GULF OF MEXICO - INDIAN OCEAN - IRISH SEA - MEDITERRANEAN SEA NORTH SEA - PACIFIC OCEAN - PERSIAN GULF - SEA OF JAPAN - SOUTH CHINA SEA - SOUTHERN OCEAN

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This website is provided on a free basis as a public information service. copyright © Climate Change Trust 2019. Solar Studios, BN271RF, United Kingdom.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||