|

HYDROGEN & FUEL CELLS

Please use our A-Z INDEX to navigate this site or see HOME

BATTERIES - COST - STANDARDIZATION - HOME - HYDROGEN - LOAD LEVELLING - PAYD - RANGE ANXIETY - RECOVERY - SERVICE STATIONS

|

|

H2020

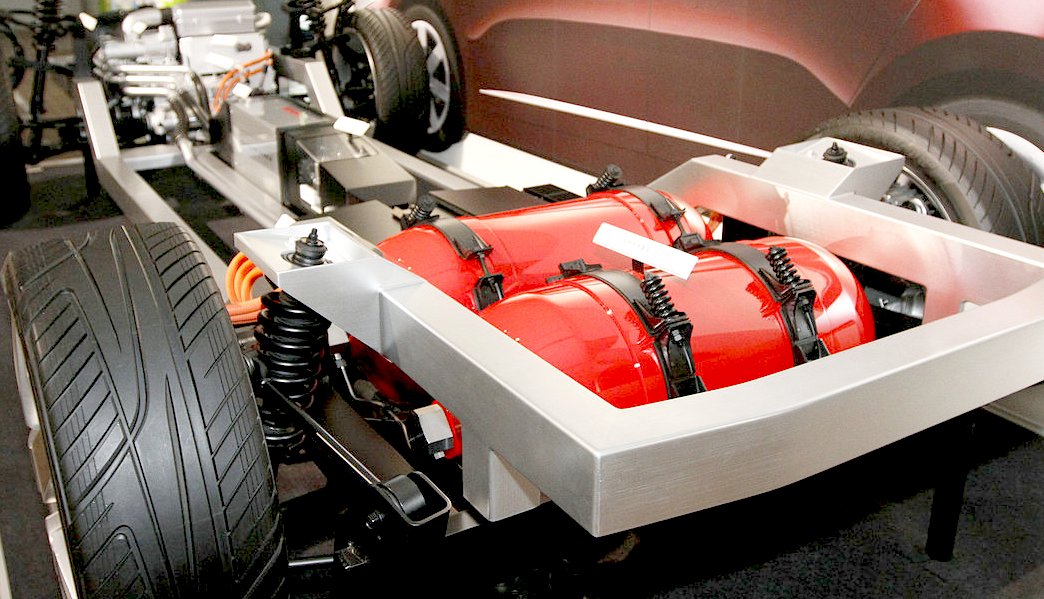

JTI-FCH-01-1 HYDROGEN TANKS FOR EV ARCHITECTURES - It is expected that vehicle architectures will change significantly in the next few years due to major trends in the automotive industry: the increase of electro mobility based on battery technology, which demands flat design spaces in car underbodies and the increasing technology readiness level of autonomous driving, which causes significant vehicle transformations including use of car interiors.

HYDROGEN FUEL CELL CARTRIDGE - It looks like a battery cartridge. It performs like a battery cartridge. It stores energy like a battery cartridge, but it is a hydrogen fuel store and/or fuel cell cartridge combination. Where lithium and cobalt raw materials may limit the production numbers of EVs as green motoring becomes the norm, hydrogen in a safe format might offer unlimited possibilities. - where the catalyst may be recycled indefinitely. The format is also compatible with air-aluminum fuel cells. The concept is compatible with SMARTNET FASTCHARGE service stations. NOTE: This is just a concept, not a product yet. More development is needed before mass production could be entertained.

Hydrogen as a renewable fuel for mass produced electric vehicles is an idea that has eluded green car makers for many years. That is because of EV architecture and the infrastructure challenge of dealing with compressed gasses and high pressures, and liquid hydrogen at freezing temperatures.

Indeed, the two technologies are quite different. They would require the development of different supply networks to provide refuelling points for gas and liquid hydrogen, though the design of the vehicle itself may not need much adaptation. It's all down to the storage tanks.

A distinct advantage would be if the energy storage bay (tank) in the vehicle was the same as with battery EVs. Then the EV could swap between battery and hydrogen power packs.

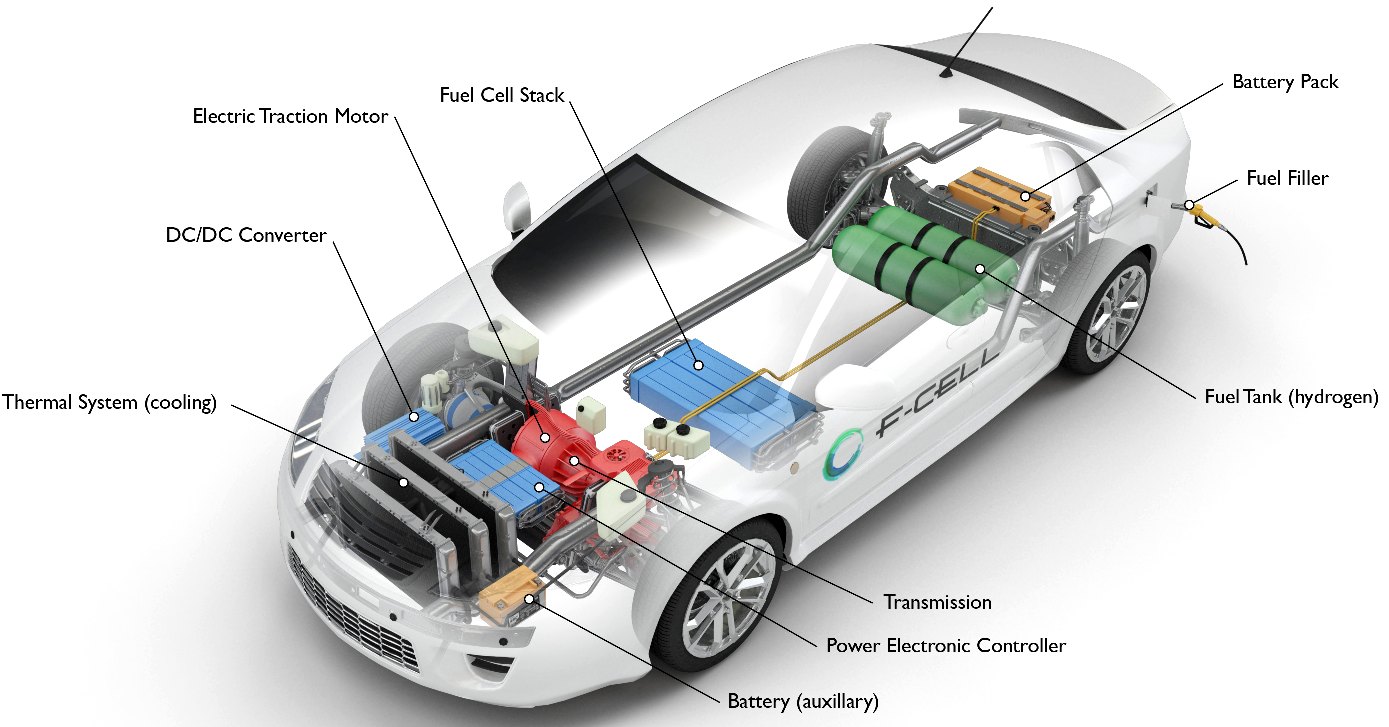

Key Components of a Hydrogen Fuel Cell Electric Car

Battery pack: This battery stores energy generated from regenerative braking and provides supplemental power to the electric traction motor.

DC/DC converter: This device converts higher-voltage DC power from the traction battery pack to the lower-voltage DC power needed to run vehicle accessories and recharge the auxiliary battery.

Electric traction motor (FCEV): Using power from the fuel cell and the traction battery pack, this motor drives the vehicle's wheels. Some vehicles use motor generators that perform both the drive and regeneration functions.

Fuel cell stack: An assembly of individual membrane electrodes that use hydrogen and oxygen to produce electricity.

Fuel filler: A nozzle from a high-pressure hydrogen dispenser attaches to the receptacle on the vehicle to fill the tank.

Fuel tank (hydrogen): Stores hydrogen gas on board the vehicle until it's needed by the fuel cell.

Thermal system (cooling) - (FCEV): This system maintains a proper operating temperature range of the fuel cell, electric motor, power electronics, and other components.

Transmission (electric): The transmission transfers mechanical power from the electric traction motor to drive the wheels.

If there was a standard vehicle layout, hydrogen would represent an ideal accompaniment to battery powered EV's potentially even replacing batteries altogether, or more likely working alongside battery storage to provide sufficient energy (hopefully) for eventual world wide zero emission transition to electric mobility. So overcoming much of the chicken and egg situation that is presently holding back progress.

We have worked out a way of using liquid hydrogen and pressurized gas in the same 'standard' cartridge dimensions that we use for battery storage. That is why we call it the Universal energy cartridge - or Super Battery. They may be used in multiples to increase range for long hauls, switching between pressurized gas and liquid at our SmartNet service stations. And that solves the infrastructure issue.

For the present time, we believe that batteries in cartridges will accelerate the adoption of EVs, but that a Universal format that allows EV owners to swap between storage chemistry interchangeably, will add significant flexibility and provide end user assurance as to future proofing. So reducing the risk of investing in clean transport for persons looking to purchase an electric vehicle.

This degree of flexibility that we are aiming for, may also encourage bus, car and truck makers to engage in the production of compatible models in their range. Likewise, generating utilities may gain confidence in the ability to supply compatible vehicles with hydrogen as a fuel, or battery based energy storage - all from the same service station because of smart energy management technology.

PRESSURIZED GAS, LIQUID HYDROGEN, SLURRY or HYDRIDE?

Assuming that we agree on the need for battery and hydrogen storage to work side by side, we then need to decide on the chemistry, layout and construction of the storage cartridges, to be able to maximize energy density.

That leaves us with a choice of what to put into the cartridge and how to do that? The EU are looking at compressed gas for cars and buses, and liquid hydrogen for long-haul trucks. At the moment, policy makers are not looking at hydride, storage.

We say why not make provision for all three current options? Or, at least make allowance for hydride combinations, while exploring the pros and cons of compressed gas versus liquid hydrogen.

Today, liquid hydrogen is the signature fuel of the American space program and is used by other countries in the business of launching satellites. In addition to the Atlas, Boeing's Delta III and Delta IV now have liquid-oxygen/liquid-hydrogen upper stages.

The European Commission and FCH Joint Undertaking, have recognized the value of adapting conventional hydrogen gas storage cylinders to a more convenient dimensional package, the same applying to liquid hydrogen containers. The former for municipal services, the latter for long range haulage.

The Cleaner Ocean Foundation agrees with these aims, recognizing that both of the formats the subject of recent calls (and the Automated & Electric Vehicles Act 2018) may fit within the same physical dimensions of a proposed Universal energy cartridge.

The objective then is to be sure that we can accommodate pressurized gas, liquid hydrogen, hydride* and slurry systems in our Universal cartridge, and that such cartridges will provide:

1. Sufficient power;

2. Be safe in operation;

3. Couple and uncouple over many years of service, and

4. Survive in a crash situation. I.e. that they are safe. And in particular, whether they might be safer than existing manually connected hose and coupling tank filling systems.

SYSTEMS LAYOUT

It appears from initial assessment that the Universal cartridge might serve us well, using a number of permutations in design and layout potentially offering the energy storage capacity that is needed for municipal buses and long haul trucks.

Given the competitive nature of proposals and funding, it would not be appropriate, to begin to rehearse the design features of these here. The main point being that it would work and could work rather well.

It remains to be seen from the proposed testing and trials which formula will come out the victor, or if there is scope and genuinely good reasons for hosting all of them in the proposed smart network.

Hydrogen fuel tanks for EVs come in two main varieties, those that contain compressed hydrogen gas and those that contain cryogenic hydrogen (super-cooled liquid hydrogen).

Liquid hydrogen must be stored at minus 423°F and handled with extreme care.

There are only a few hydrogen fueling stations which dispense cryogenic liquid hydrogen. This is mainly because almost all of the major carmakers have chosen to fuel their prototype cars with compressed hydrogen gas.

Other manufacturers are using metal hydride technology where hydrogen is stored the porous metal hydride material then the gas is released by adding a little heat to the tank. The drawback with using metal hydrides in hydrogen fuel tanks is that they are generally very heavy. This weight then cuts down on the MPG’s of the vehicle. Creating a 20-gallon fuel tank prototype from metal hydrides or carbon nanotubes can add up to $30,000 to the price of a car.

LOAD LEVELLING

As an energy carrier, hydrogen offers virtually limitless capacity to store solar and wind renewable energy, to be released when it is needed. The fact that no rare metals are needed for such storage, may give hydrogen a future market edge.

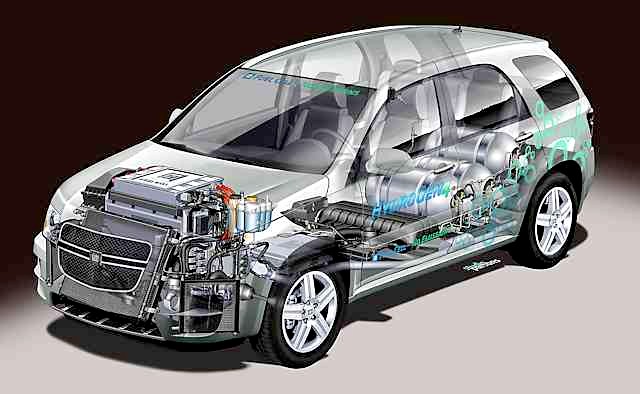

EXTRA TANKS - There are many variations on the layout of hydrogen and battery EVs. This Hyundai Tucson is the world's first commercially mass-produced hydrogen fuel cell vehicle. She can travel 370 miles on fill up of hydrogen. More than the 265 miles of a fully-charged electric Tesla Model S. This improvement in range is due in part to the Tucson ix35 FCEV's greater space for holding compressed hydrogen, at a higher storage pressure, as well as fuel cell technology advances, including the first type IV hydrogen tanks for compressed hydrogen at 700 bars (70 MPa; 10,000 psi).

BATTERY CARTRIDGE FORMAT PROPOSAL - This cartridge format provides 0.24 of a meter cubic capacity. All of these formats can be used in multiples to provide up to 1.92 of a cubic meter capacity. This is one of a number of sizes that we will be evaluating as part of a study we hope to obtain funding for. It is only with this system that vehicle operators can enjoy Pay As You Drive (PAYD) economy.

PEM FUEL CELL - The most common type of fuel cell for vehicle applications is the polymer electrolyte membrane (PEM) fuel cell. In a PEM fuel cell, an electrolyte membrane is sandwiched between a positive electrode (cathode) and a negative electrode (anode). Hydrogen is introduced to the anode, and oxygen (from air) is introduced to the cathode. The hydrogen molecules break apart into protons and electrons due to an electrochemical reaction in the fuel cell catalyst. Protons then travel through the membrane to the cathode.

A SENSE OF URGENCY & COOPERATION

With something so crucial as cars and vans in terms of efficient transportation and climate change, we believe that auto makers should agree on a universal energy format, relying on the design of the body, performance of motors and comfort levels to distinguish brands.

They already do this with internal combustion engines and chassis platforms, sharing the cost of designing and producing the main running components of several brands, such as the PRV V6 engine that was shared by Peugeot, Renaut and Volvo in the 1980-90s. Honda and Rover had a similar arrangement in the 1990s.

The

Skoda Scala utilises the smaller MQB A0 platform found in the VW Polo and

Audi A1.

We believe that it would help the transition to zero emission vehicles, if there was a joint venture much like the above, to define an electric platform that could use battery or hydrogen cartridges.

BADGE ENGINEERING

The practice is also referred to as "badge engineering," where an automaker can create the illusion of an "all-new" model simply by changing the badges, the grille and other superficial styling details, should they not wish to develop a new car from the chassis up.

The only reason for not cooperating is to artificially maintain the sales of their IC engine models to recover as much as they can from their investment in production tooling.

We might offer that once a model is outdated, that new ICE models should not be developed as being counter to the creation of a Circular Economy. We are in the middle of a climate emergency, after all.

Because it has so many brands under one corporate parent, General Motors is the classic example of a company that found efficiencies by issuing virtual carbon copies of its cars across numerous brands. But in today's world of customization and target marketing, the company is tailoring its vehicles to appeal to different customers.

"While it's true that the vehicles share common chassis and powertrain attributes, really the customer doesn't see or touch these 'black metal' attributes. We've really worked to differentiate and distinguish the models from the standpoint of exterior and interior design. So, for example, the Traverse's sheet metal is mostly unique, sharing only its roof and

lift-gate with its siblings. Its dual-cockpit design — the way the dashboard arches up from the center stack on both sides — is unique to Chevrolet and harkens back to Corvettes of 50 years ago. The instrumentation and door pads are also unique to the Traverse."

EXAMPLES OF EV RANGES - For most users, 100 miles range would allow the shopping run and visits to the folks and friends, without too much of a panic about range limitation. As soon as this range is exceeded, these cars become useless in terms of replacing petrol and diesel cars. What is needed is an infrastructure that replaces the convenience of fossil fuel servicing with the advantages of zero emissions and renewable energy, to create a truly sustainable society in United Nations' terms: SDG 7, 11 and 13.

TRANSPORT INFRASTRUCTURE

By working together to establish an energy supply infrastructure, manufacturers might then concentrate their efforts on styling, without having to worry that their machines will not be able to share in the new green revolution on terms that are fair.

We'd also prefer to see customers reaping the benefits of clean motoring, economically, without having to limit themselves to fast charge, that tends to shorten the life of batteries and places extra loads on the National Grid of their country.

BETTER ALL ROUND

As with power tools, customers might not have to pay for the mistakes of manufacturers in getting it wrong, as they also seek assurances for where they put their hard earned income.

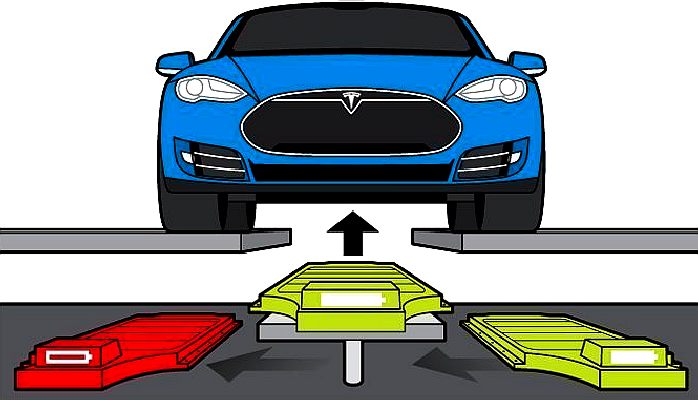

TESLA S CARTRIDGE EXCHANGE - This concept is not a million miles away from SMARTNET, except that the underground method makes it expensive and complicated. This is a variation of the Better Place system. The point here is that with a bit of tweaking, FASTCHARGE can be made to work in practical terms.

PRIOR ART

1900 - Cartridges as an energy transfer medium were first used by Professor Porsche in the early 1900s. He then increased range with petrol dynamo and gave up when petrol cars got electric starter motors.

1990 - Buses with cartridge exchange were used at Kobe, Japan, in the 1990s.

2009 - The next serious attempt to perfect the concept came with Shai Agassi's 'Better Place' system, using service stations in Denmark and Israel, but only for batteries as the energy storage medium. The service stations were expensive and the loading mechanism complicated, but were still planned for California, but the company folded in 2013.

2013 - Elon Musk came next with a Tesla S production vehicle modified to swap cartridges. Once again the underground (or above ground stage) required expensive installations, and this system was only for battery cartridges. Tesla is now concentrating on rapid charge stations.

The proposed SmartNet system aims to resolve the issues identified from the Better Place and Tesla systems, by incorporating fuel cells in standard cartridges as future proofing and reducing the buy in cost with networked flat pack service stations that any utility, supermarket or energy company might operate.

BETTER PLACE - Better, it might have been, but future proofed enough for a developing market, it was not. This early battery cartridge exchange station from Better Place, was a stepping stone in the evolution of the electric vehicle. We should not undervalue the efforts of those brave engineers who took a chance and failed. Because with each failure we know to look elsewhere for a solution. The epitome of perseverance in the face of adversity is Thomas Edison, when developing the incandescent light bulb.

CONTACTS

Solar House BN27 1RF, United Kingdom PIC No: 895922168

LINKS & REFERENCE

https://www.cryofab.com/products/clh_series https://www.cryofab.com/ https://www.eleetcryogenics.com/ http://www.shell-n-tube.com/product2.html https://csabg.org/liquid_hydrogen_tank_systems/ https://augustecryogenics.com/liquid-hydrogen-tanks/ https://www.vrv.com/cryogenic-division/hydrogen-tanks/ https://www.linde-engineering.com/en/plant_components/cryogenic_tanks/index.html https://ec.europa.eu/easme/en/section/sme-instrument/eic-accelerator-sme-instrument-funding-opportunities

BATTERIES - COST - STANDARDIZATION - HOME - HYDROGEN - LOAD LEVELLING - PAYD - RANGE ANXIETY - RECOVERY - SERVICE STATIONS

Please use our A-Z INDEX to navigate this site

|

|

|

This website is provided on a free basis as a public information service. copyright © Climate Change Trust 2021. Solar Studios, BN271RF, United Kingdom.

|